- Infrastructure

- Testing Facilities

Testing Facilities

Every product of ours is tested in accordance to international standards of quality & performance. We have our own stringent testing facilities & procedures, which is developed considering the tough working conditions. Furthermore, we also have the facilities to offer specific testing as per client's specifications. Also have an look at our Measuring Instrument & Testing Facilities.

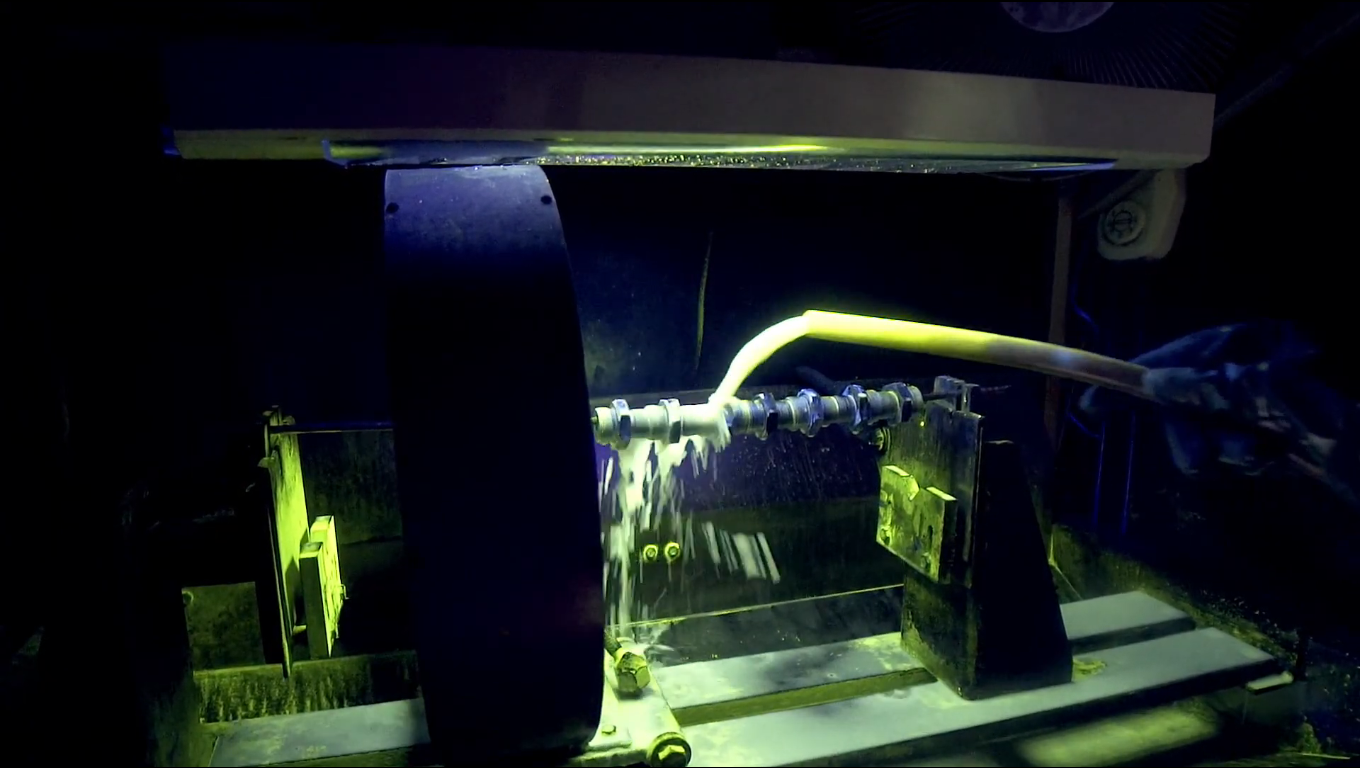

Computerised Multi Test Bench

We have facility to test hydraulic fitting, tubes, hose pipes ets. We test above our applications under various tests including hydrostatic proof test, burst test, vacuum test, impulse test, impulse plus vibration test, flex fatigue test, pull out test etc.

Gauges & Instruments

We have complete set of gauges at our Plant Like Ring Gauges & Plug Gauges of all Threads like Metric, BSP, taper threads,Snap Gauges,Pipe Gauges, ED Gauges, Also Coating thickness of Plating are checked with Plating Thickness Tester.

A complete system of logging is maintained for calibration certification for all equipment, gauges, measuring instruments etc. to ensure that their calibration remains valid at all times.

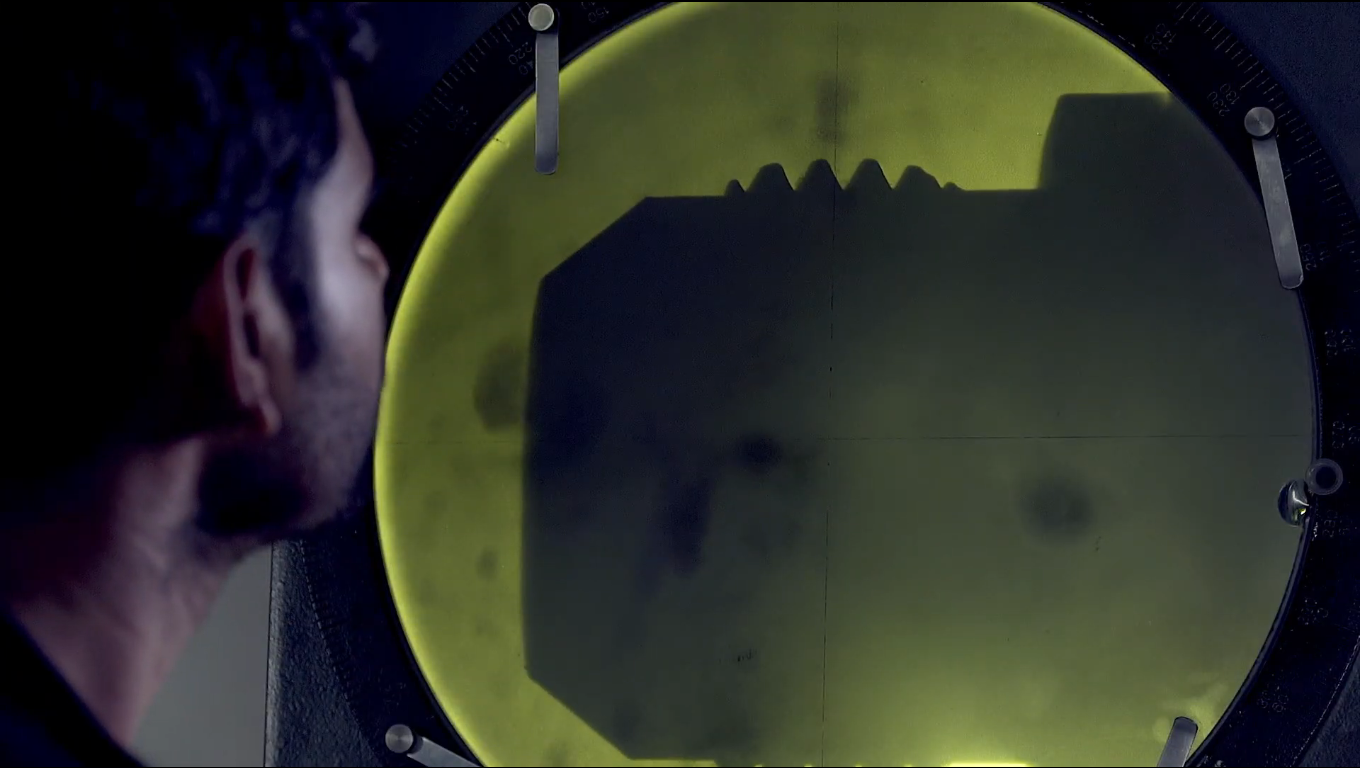

Profile Projector

The profile projector magnifies the profile of the specimen, and displays this on the built-in projection screen. On this screen there is typically a grid that can be rotated 360 degrees so the X-Y axis of the screen can be aligned with a straight edge of the machined part to examine or measure.This projection screen displays the profile of the specimen and is magnified for better ease of calculating linear measurements.

All our Units are having Profile Projector facility to check the critical angles, Radius & threads Profile of fitting as per Standard.

Salt Spray Test

Salt Spray test is widely used in the industrial sector for the evaluation of corrosion resistance of finished surfaces or parts in order to predict its suitability in use as a protective finish. The appearance of corrosion products (oxides) is evaluated after a period of time. Test duration depends on the corrosion resistance of the coating.

Hytech is having In-House Salt Spray Testing Facility at all our Units to ensure that all supplied fittings are properly Coated & defines strength to prevent the corrosion on surface.

Millipore Test Set Up

Hydraulic Sector demands all components should be free from foreign particles,dusts, So Millipore test is done to find out the exact value of such particles with the help of Filter Papers.

Millipore test is carried out for Hytech fitting. Hytech is having In-House Millipore Testing Facility at all our Units.

Rockwell Hardness Tester

The Rockwell test is generally easier to perform, and more accurate than other types of hardness testing methods.The Rockwell method measures the permanent depth of indentation produced by a force/load on an indenter.

All In-Coming Material at Hytech are checked for Hardness at their Initial stage. We will assure that all fittings of Hytech are ready to used in High Pressure Manufacturing sector.

Surface Roughness Tester

Flow Control Components of industries requires highest level of surface finish to prevent the leakage.Surface roughness tester is quick, easy and accurate Ra measurement equipment used in hydraulic industry. Hytech Fittings are designed and manufactured to meet all the requirements as per drawing and most suitable for this application with consistency, reliability and safety.

Crack Testing

Crack Testing is one of the oldest and simplest methods of the non-destructive testing (NDT). Crack Testing also known as MPI (Magnetic Particle Inspection) is a method that can be used to find surface and near surface flaws in ferromagnetic materials such as steel and iron it is primarily used for crack detection.

All Hytech Fittings are 100% inspected for Crack test. All Hytech units having In-House Crack Testing Facility at all our Units to ensure that all supplied fittings are able to withstand high pressure, vibration, pressure Variation etc.